| What's Hot! | Products/ Tools | EFI Tuning | Basic Tuning | Advanced Tuning | Chassis Tuning | Advertise with us |

Figuring out the driveshaft for the awd civic

Contributed by: Enginebasics.com

If someone would have said the driveshaft would end up being the biggest headache of this whole build I would have told him or her they were crazy. Truth be told, it has been a nightmare. It all started with getting some bad information about shortening carbon fiber drive shafts. I called a company that makes carbon shafts and asked over the phone if they can shorten carbon fiber drive shafts. I got the response of “sure can, would be between $450-$500 depending on how much we had to take out”, and I hung up. Perfect, and with that out of the way in the planning of the project I left it alone till it was time to get the driveshaft shortened and install it.

If you didn’t know, Acura threw all the magic they had at the RL in 2004 when they started designing their new flagship model that would be released in the States in 2005. It even came with a Honda first, a carbon fiber 2 piece drive shaft. What a sexy piece it is too.

I was super excited to get to have a carbon fiber driveshaft on the build for just $500 bucks. I called the same drive shaft shop back and said, “hey I want to send in my driveshaft and get it shortened and I have my measurements all done”. They responded with “this is one of our companies shafts right?” I said “no, but I had called about 9 months ago and talked to someone that told me over the phone that you guys can shorten carbon shafts”. And this is the part where everything starts to head south. They said they can ONLY shorten the carbon shafts THEY MAKE, and cannot do anything for me. As you can imagine I was pretty upset that this information hadn’t been told to me before when I called. Wouldn’t you think that would be a pretty important question to ask if someone calls up and asks if you shorten carbon fiber drive shafts? What can I say? I should have realized that the people answering the phones at most of these companies are making minimum wage and so the information you get is about what you paid for.

With this information I start calling some of the major driveshaft shops that do custom stuff. At first I wanted to eliminate the complexity of a two-piece shaft and go with a single piece for two reasons.

- Less weight and “slop” in the shaft

- Less fabrication since on a two piece shaft you have to mount the center carrier bearing.

After doing some research though I learned about something called critical speed. You see, there is this speed where the shafts own weight and spinning speed will be so great that it’s own force will break it apart. The only way to combat this is by making the shaft lighter or making it stronger by increasing its diameter. Because of the length of a driveshaft on a transverse mounted engine, I had extremely low critical shaft speeds. So low in fact, that if I would have gone with a standard steel 3” shaft I would have had a critical speed of just around 100 mph. Easy then to see why many transverse AWD set-ups, like a Mitsubishi Evolution (evo), or a 3000GT/Dodge Stealth have two and even three piece drive shafts. By breaking the shaft into pieces, each shaft behaves as a smaller shaft, which raises its limit of rotation.

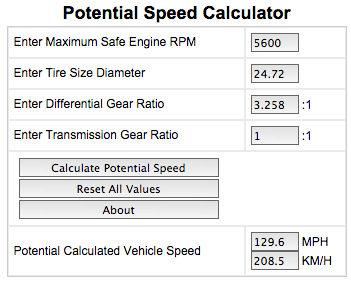

Knowing that my goals for the car were to maybe one day do ½ mile events I needed to have a drive shaft that would be stable to 170+ MPH. I then started to do the math on an aluminum 4” shaft. Based on my gearing and specs though I found that a 4” aluminum shaft would be good to around 129.6 mph.

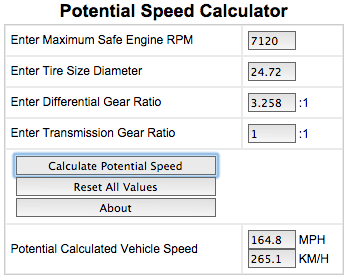

Now granted, these were very conservative numbers but I certainly wouldn’t have wanted to take the car much over 135. At this point I see that I’m going to have to go to a 5” aluminum shaft at a minimum. I calculated its critical speed and got a MPH of 164.8.

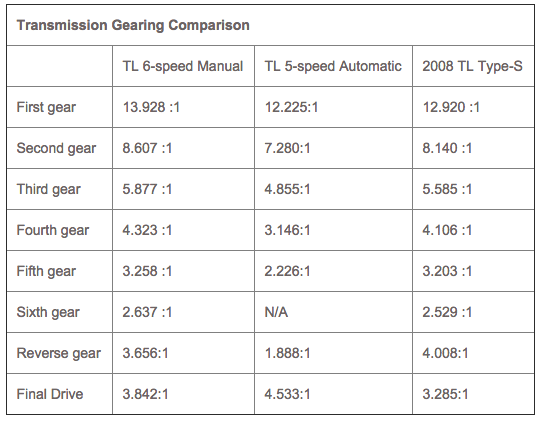

Both of these calculations were done using the 5th gear ratio. Going into 6th gear just isn't going to happen under WOT condition so who cares. Here is the ratio's for the 6 speed transmission. (click for larger image)

Not bad, but not great either. Again I wouldn’t feel that great about taking this shaft much above that, but it would do. I then started calling and getting some quotes.

There are only about 3 companies that have the equipment and expertise to make such a long single piece driveshaft in 5” aluminum with custom flanges at either end. Get ready to prepare yourself, because I got BLOWN AWAY. The first company I called quoted me $3,750 for a 4” aluminum shaft and would have to get back to me on a 5” if I wanted to go that big. I told them not interested. Second company came in at $3200 for a 4” aluminum shaft and told me they didn’t have the ability to do a 5” shaft. The last company was going to be the cheapest at $1800 for a 4” aluminum shaft, but agreed with me that the speeds would not be enough and I would need to go to a 5” shaft in which I could expect the price to double and be somewhere around $4,000 dollars do to the rarity of producing such a thing.

At this point I am literally depressed. While I love this project to death, half of the appeal of it was that I was going to have a super fun car for less than $5,000 dollars after selling off the donor parts. So far the prices I was getting on a driveshaft were going to cost more than the entire car up until this point. I now realize I will need to do a two-piece shaft to get the critical shaft speeds where I want them to be and will need to ditch the idea all together of having a super trick carbon fiber driveshaft on the cheap. Heck, I will be happy with a steel one that just gets the job done at this point.

A conclusion to the driveshaft conundrum will have to come at another time. At this time its looking like I am going to have two adapter flanges built that will go from a common two piece steel shaft and convert to my transfer case upfront, and my rear differential in the rear. This shaft will still be pricey but should be able to come in under $1000 dollars, which still sounds ridiculous, but at this point is doable.

What a roller coaster ride this has been! I don’t know what I would do if I literally had no other options and had to spend $1,800 on a shaft that would have restricted the cars top speed to around 130 mph. Soon as the final solution is in my hands and mounted on the car I will update this article. Until then, wish my wallet luck.

ATTENTION READER:

If you enjoyed the information and article you just read be sure to check out our newly released book with even more exciting photo's and information:How to Turbocharge and Tune your Engine

Want to know more about your particular Make and Model vehicle? All of these vehicles are covered in the tech, maintenance and repair articles found above. Enginebasics is the wiki or wikipedia of car part, repair, how to and tuning information. Let us be the class 101 for your automotive learning.

| Ford | General Motors GM | Pontiac | Jaguar | Land Rover | Nissan |

| Toyota | Honda | Lexus | Acura | Lotus | Scion |

| Infinity | BMW | Mercedes | Mitsubishi | Ferrari | Maserati |

| Lamborghini | Volks Wagen VW | Saab | Audi | Hyundai | Kia |

| Subaru | Mazda | Chevy | Volvo | Caddilac | Dodge |

| Chrylser | Daewoo | Porsche | Mercury | Freightliner | MG |

Individual Models

| Ford Mustang | Mitsubishi Eclipse | Mitsubishi Evo | Subaru WRX / STI | Dodge Viper | Chevrolet Corvette |

| Nissan Skyline | Honda S2000 | Nissan 350z | Toyota Supra | Chevy Camaro | Lotus Elise Exige |

| Honda Civic | VW Golf | Dodge SRT-4 | Eagle Talon | Acura Integra | BMW M3 |

| Nissan 240sx | Porsche 911 | Acura NSX | Honda Accord | Toyota Camry | Toyota MR2 |

| VW R32 | Dodge Truck | Mazda Rx7 | VW Jetta | Sand Buggy | Nissan Sentra |

For the latest Automotive news and stories visit the websites below |

Our feature Build: An AWD V6 Civic